Circular economy: there is potential here for companies – from resource efficiency to new business models

A circular economy enables companies to meet ESG requirements, lower production costs and reduce their dependence on commodity markets. But what is behind the principle of the circular economy and how can it be implemented in a corporate context?

According to the EU Parliament, the European Union alone produces more than 2.5 billion tons of waste every year. Waste prevention, ecodesign, reuse and similar measures could reduce the resulting emissions. At the same time, recycling would reduce dependence on commodity markets and lower production costs, which is becoming increasingly pertinent for companies in the face of political crises and inflation. This is where the circular economy comes in, with reusable and more innovative products and more sustainable production processes.

What does “circular economy” mean?

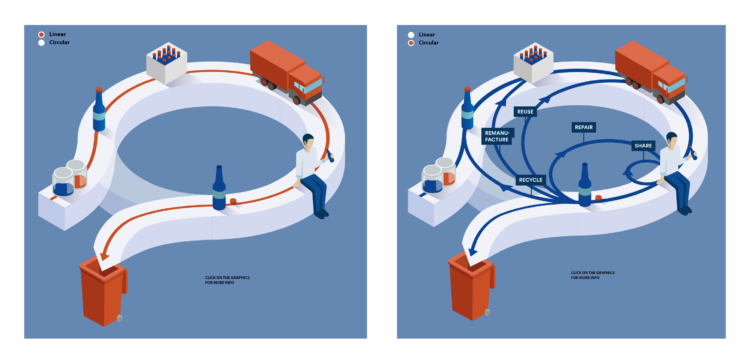

People have been using natural resources to meet their needs for consumer goods and to drive economic development since time immemorial. However, at least since industrialization, this use has increased to a level that is not sustainalbe any longer. The consequences are depleted resources, ever more waste and increasing pollution. The circular economy opens up a solution to these problems. The traditional, linear economic model with its “take-make-waste” approach is replaced here by the idea of a closed cycle in which resources are reused for as long as possible. The circular economy is changing the way we think about the life cycle of services and products and aims to conserve as much energy and resources as possible for future generations.

In 2015, the EU set itself the goal of paving the way for the circular economy in Europe with the first Circular Economy Action Plan. This plan is also intended to lay the groundwork for achieving the EU’s climate neutrality target by 2050.

Advantages of the circular economy for businesses

Beyond protecting the environment, the circular economy has a positive impact on numerous commercial factors, such as:

- Creation of jobs and strengthening of the local economy through reduced dependence on imports

- Cost savings and increased competitiveness through more efficient use of resources and waste prevention

- Tapping into new markets and business models by designing new products for the circular economy

- Improved image in the eyes of customers, employees and applicants as a result of sustainable business practices

- Improved financing options thanks to demonstrably reduced sustainability risks

- Compliance with growing statutory ESG obligations

Challenges of introducing principles of the circular economy

Why do many companies still often rely on principles of the linear economy, even though the circular economy brings it many advantages with it? A critical reason is the lack of transparency around waste generation and emissions, as well as the value of recycling that waste. Political and regulatory frameworks could promote and even necessitate such transparency in the future. For example, the EU is currently drafting guidelines and standards such as the Ecodesign Directive and the digital product passport. If it becomes mandatory for products to carry this passport, information about the substances they contain, suitability for repair and recycling rate will be transparent for each product.

There is also still a lack of collaboration between organizations, as well as a lack of expertise and resources to implement circular economy practices effectively. However, more and more companies are catching up in this respect, with the result that circular economy expertise will become a decisive factor for market competitiveness in the long term.

Is sustainability the answer to surviving crises? Companies are starting to realize this now more than ever

Why are ever more companies focusing on sustainability? What are the drivers behind this trend? Our sustainability specialist and ESG consultant Dr. Michael von Papen […]

How can circular economy principles be implemented in a corporate context?

A systematic approach is required if a company is to develop circular economy products and services within its own organization. An initial assessment should evaluate existing practices, monitor the flow of materials and in doing so identify opportunities for improvement. One method of assessing products is known as lifecycle assessment, which looks at the product’s impact on the environment over its entire lifecycle – from creation to disposal. The next step should be to formulate appropriate goals within the organization that outline the path toward a circular economy model. Actually, meeting these goals often requires the involvement of multiple stakeholders, designing new circular economy products or service-based business models, and monitoring material cycles on an ongoing basis. As part of this, there should be continuous monitoring of the extent to which products and services fit into the circular economy in order to document progress and uncover further potential for improvement.

However, the transition to a circular economy cannot happen in one big bang, but must be seen as a comprehensive strategy that is implemented on an ongoing basis, taking into account every aspect of business operations – including the production, use and disposal of resources.

Data pave the way from a linear to a circular economy

Data-driven companies are already well positioned to transition to a circular economy, as they can track all the data along their value chain. For example, they can use ESG dashboards to view every stage of their production and supply chain, enabling them to identify from the outset where waste is generated that can be reintroduced into the production process and recycled.

When AI-based forecasting is added, fluctuating sales, for instance, can also be predicted very accurately and orders can be adjusted to reduce the amount of raw materials that need to be stocked and ultimately are not used. This is particularly relevant for perishable goods, e.g., in the food industry. In other production areas, too, inventory management can be optimized through targeted merchandise planning, which in turn can reduce emissions caused by heating, cooling or ventilation systems, for example.

3 examples of circular economy solutions in companies

Data & AI minimize wastage

In production itself, material fluctuations repeatedly result in products being manufactured that do not meet quality standards, such as in the production of medicines or in the automotive sector. In the best scenario, raw materials they contain can be recycled; in most cases, however, the rejects have to be sorted out and disposed of. In terms of sustainable production, production data and artificial intelligence can be used to intervene at an earlier stage: for instance, injection molding machines that produce engine parts or systems for pharmaceutical primary packaging could react to material fluctuations and adjust production in such a way as to reduce waste.

Smart maintenance improves machine longevity

One approach to saving emissions and resources is to make products as durable as possible. This begins with the machines that manufacture them. Data-driven maintenance, in which potential changes to machines are simulated and any damage is predicted, can improve the maintenance process and thus extend the service life of the machines. If they function smoothly, this in turn has a positive effect on achieving consistent quality in the goods they produce.

Intelligent waste sorting

No matter how much waste may be saved, a certain amount remains and must be disposed of. However, ensuring that waste is disposed of in an environmentally friendly manner is not in itself the only aspect to be considered. The sorting process can also be optimized. This is where AI can help in recycling plants: materials are recorded more accurately, sorting becomes more precise, and a greater proportion of valuable recyclable material is used.

In summary, the circular economy is an important driver for creating greater sustainability in terms of the environment and from a commercial perspective. If you would like to discuss this topic, please contact our ESG Consultant Dr. Michael von Papen and his colleagues: you can get in touch with them here.